An Andon board creates transparency and responsiveness in lean production!

Andon-Board — Communicate clearly, alert quickly, motivate employees, increase efficiency!

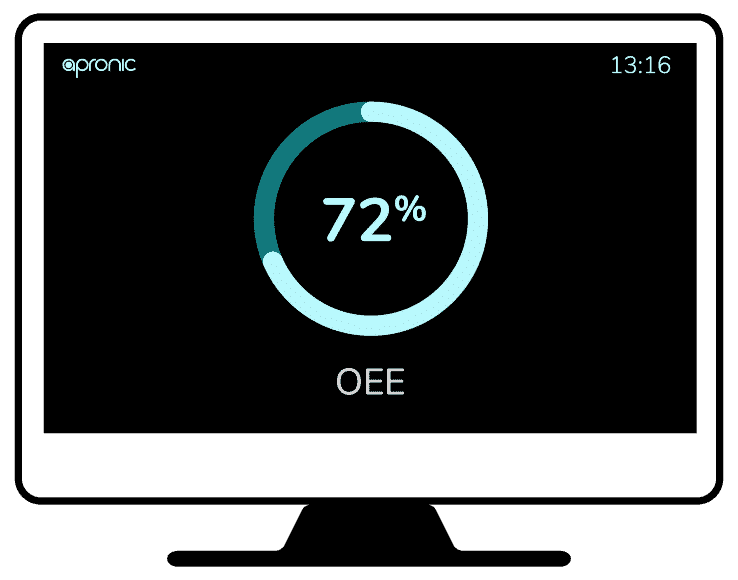

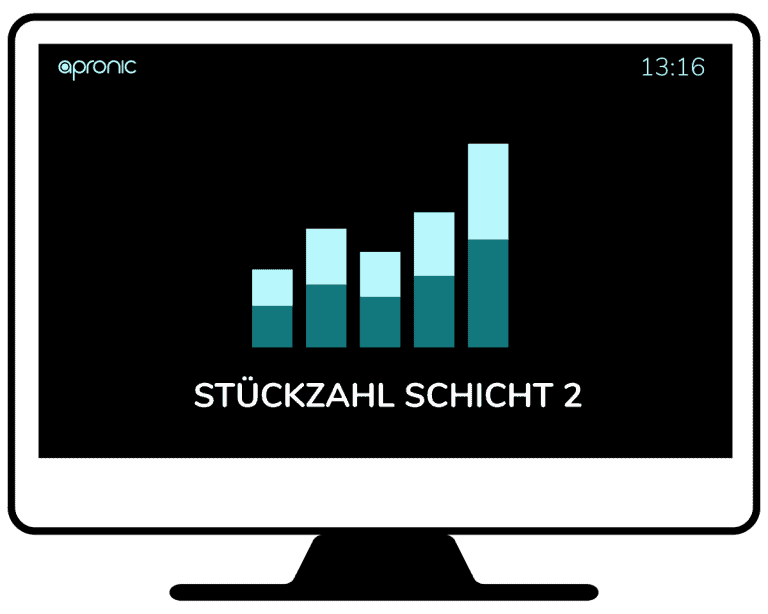

Visualize key figures and clearly communicate goals with an Andon board and production control stations and keep an eye on downtimes at all times! An Andon board creates transparency — so everyone in production is on the same level of knowledge.

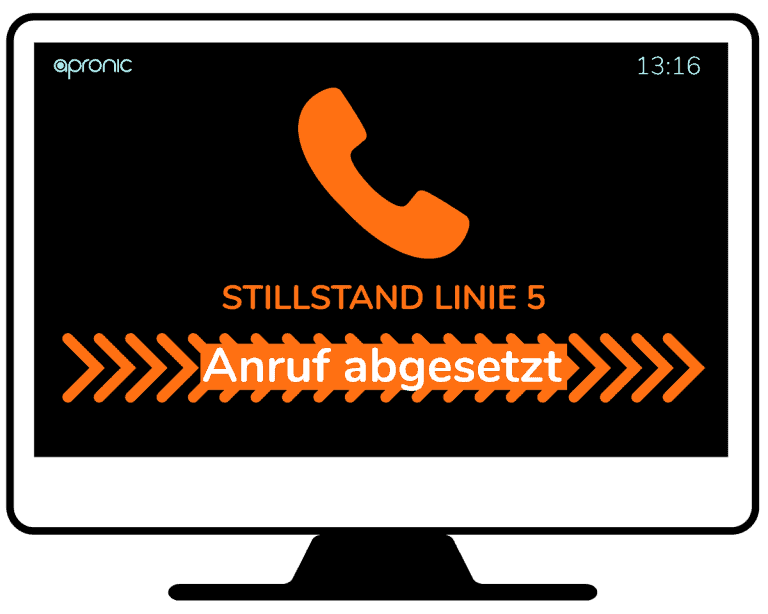

Faster alerting through digital fault messages reduces the response time to downtimes. Categorized error messages also enable process optimization and the targeted elimination of the causes of malfunctions.

Fault reports are useless if they are not delivered to the right people. Get automated information about malfunctions or downtimes via app, smartwatch, phone, SMS or e‑mail.