production made transparent

In everyday life, we see similar challenges and issues with many of our customers. In the end, they all revolve around increasing competitiveness, especially in a high-wage country like Germany. This can be achieved through different approaches, but first of all transparency must be brought into the production processes and valid actual data must be recorded. All this can be simplified by digital assistance solutions like prodwatch. With prodwatch, you as plant manager can obtain important information at a glance, such as the current status of production and individual workstations, actual quantities, cycle times and many other key figures and information. As an employee at the workstation, you gain security in assembly and a quick reaction to unplanned disruptions. With the foreman call and department calls, the appropriate support can be called directly, who are then alerted via smartwatch or e‑mails. The quality managers and the manufacturing engineering departments also obtain a wide range of information about products and the manufacturing process, which is incorporated into the continuous improvement process.

Knowing what works. And above all: What is not working?

Where and why do such high costs arise?

In which processes and work steps are the causes?

How do we inform, motivate and train our staff?

Do you know these questions and problem descriptions?

With prodwatch, these questions no longer remain unanswered and Industry 4.0 becomes much more than a buzzword or an end in itself!

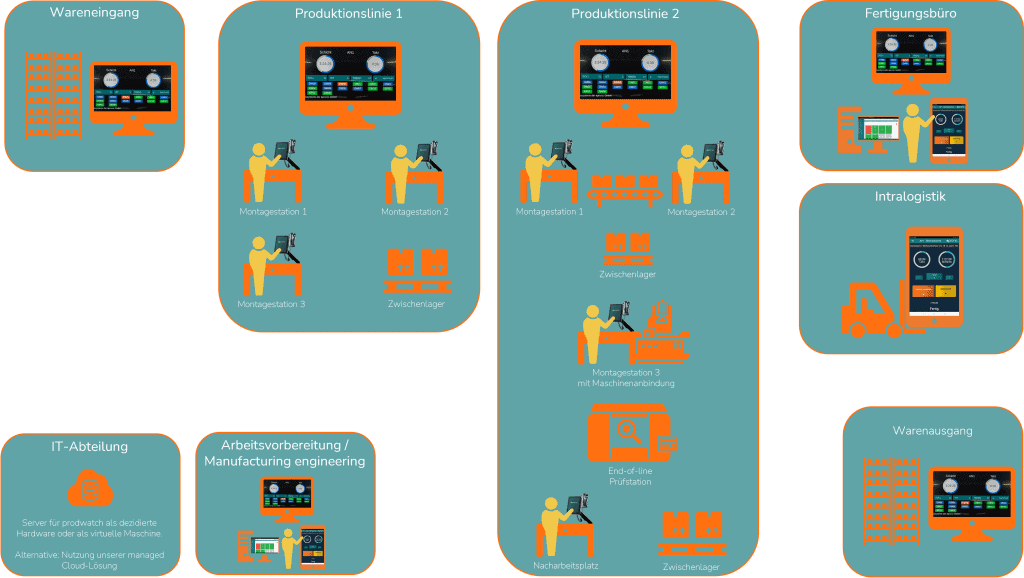

prodwatch is an all-in-one solution for the digitisation of assembly workstations. Each workstation relevant to the production process is equipped with a touch panel. This enables a variety of interactions with the worker and the production process. In this way, current information can be distributed and malfunctions can be quickly reported and remedied. Shift and production supervisors or maintenance can use smartwatches or an email alert to be quickly called to the site. Large displays in the factory halls and production offices create a clearly visible transparency of production, giving you an overview of the production status at all times. With the integrated worker assistance functions, individual work steps can be documented and processed with guidance. This makes it possible to quickly train new employees. It also ensures documentation security and traceability of individual products. With the resulting data, our customers optimise, for example, the synchronisation of production and eliminate the causes of frequent or long-lasting malfunctions. Some of our customers achieve amazing results with this (figures are estimated statements from a total of 5 customers):

prodwatch is deliberately modular in order to support the continuous improvement process. Many of our customers start with an andon application, i.e. the display and alerting of faults or other operational messages. This is then usually the nucleus for a variety of ideas that can be implemented ex works with the help of prodwatch and its numerous functions. We offer a total of three software modules:

The three software modules build on each other. The work&trace module thus contains all the functions of prodwatch. In addition to the production-specific functions, the software solution naturally also includes comprehensive user management, a shift calendar, event/action logic and extensive interfaces to the machine and business software world. Thus, prodwatch offers you a scalable toolbox for intelligent shop floor management and the digitalisation of your manufacturing processes.

From goods receipt through production to goods issue, every product, every work and inspection step and every key figure can be seamlessly tracked. In the incoming goods department, incoming goods inspections can be carried out securely and documented using input terminals. Production benefits from digital work instructions and transparent key figures. Malfunctions can be pointed out quickly and easily via touch terminals. In the outgoing goods department, checks can be carried out using digital work instructions.

The production or manufacturing manager has an overview at all times through displays in the production office or mobile devices such as smartwatches or tablets. Maintenance and materials management also have an overview of current disruptions or material requirements. Changes to work instructions, quality notifications or other key figures are possible at any time.

This makes the production process transparent for all departments involved. All data on products and processing steps are recorded continuously and enable detailed evaluations and optimisations of your production.

Our all-in-one solution also includes an extensive range of touch panels and touch pads for the assembly stations, large displays for Andon boards, smartwatches and a comprehensive portfolio of accessories. These include RFID identification systems, barcode scanners, machine interfaces and much more.

apronic GmbH

Handwerker Gewerbepark 8

48282 Emsdetten