Digital worker assistance systems create transparency, increase assembly quality and open up a wide range of optimization potential!

Increase manufacturing and assembly quality with digital auxiliary tools

Fast onboarding of new employees and increase in employee performance

Reduction of complaints and rejects through precise display of instructions

Complete documentation, visualization and analysis of the manufacturing process for quality optimization

Challenges in everyday manufacturing

The modern manufacturing of products constantly poses new challenges for production employees, quality departments, maintenance, materials management and also production management:

- Shorter and shorter cycle and throughput times through process optimization

- An increasing number of variants of the end products up to “quantity 1

- Frequently changing employees due to fluctuation or the use of temporary workers

- Increasing quality requirements of end customers and documentation of manufacturing quality

- Continuous production optimization by shifting work steps to other assembly stations

prodwatch addresses these problems with a unique combination of industrial hardware and suitable software for a wide range of functions in the digitization of assembly workstations. In addition to the simple display of pdf documents at the workstations, the worker assistance system also brings detailed step-by-step instructions for any number of product variants. In this way, entire assembly processes can be mapped using checklists, image and video recordings, pdf documents, material lists and much more. You can easily create the work steps yourself with the integrated drag-and-drop editor and refine them further and further. By using the work steps defined in this way, a data treasure of your production is created, which you can use for production optimizations or process improvements. With prodwatch you become a little bit better every day!

Digital assembly stations with prodwatch worker assistance

Intelligent worker assistance systems like our prodwatch solution enable you to solve these challenges. With the help of digital end devices such as tablets or touch panels at the individual workstations, information about the assembly process can be communicated easily. Documents such as drawings or work plans no longer need to be looked up in file folders, but can be accessed at the touch of a finger. Step-by-step instructions provide new employees in particular with confidence, even for complex assembly work. Incorrect assembly or other quality problems can be minimized or even completely avoided through integrated checks. This reduces waste and ensures satisfied end customers for your products. However, if errors or questions arise in the assembly process, the employee can alert the shift supervisor or other departments directly. All data on the manufacturing process is stored centrally in a database and can be used for optimizations or also a quality certificate for your customer.

Our whitepaper on the topic of worker assistance provides you with numerous ideas and implementation tips!

Our free whitepaper gives you practical ideas and implementation suggestions for your worker assistance system. From the simple display of pdf documents to comprehensive step-by-step instructions for different product variants, much is already possible in the standard with prodwatch. Let us inspire you!

Diverse functions lead to transparency in your assembly processes

In practice, there are many different functions of worker assistance systems. In principle, every digital tool in manufacturing is a component of a manufacturing assistance system. When selecting software for assembly digitization, it is important to ensure that the solution is scalable. Thus, we recommend that our customers start with a test system or with a simple range of functions and build up the solution in an agile manner, i.e. gradually, as part of the continuous improvement process. The most important functions, which are very often the starting point for the introduction of a worker assistance system, are listed below:

- Display drawings, material lists, work and test plans, general information such as canteen plans or accident prevention regulations and many other pdf documents directly at the assembly station

- Clearly present step-by-step assembly instructions for complex, multi-variant end products

- Graphical editor for the creation and continuous development of work steps with diverse graphic widgets such as images, videos, checklists, pdf displays, text blocks and much more

- Work steps can be freely assigned to individual work stations via drag-and-drop, thus enabling optimal synchronization of production lines via actual time recording

- Work steps can be freely assigned to individual work stations via drag-and-drop, thus enabling optimal synchronization of production lines via actual time recording

- Interfaces into the machine environment to integrate test and machine data into the digital assistance solution. Work steps can be completed via machine signals (EOL test station).

- Display of general company message texts and the status of all workstations at the individual assembly stations

Create work steps quickly and easily with the visual editor!

Many work and assembly steps in production processes are constantly being optimized and adapted. New products are also coming onto the market at an ever faster frequency and have to be manufactured in new production processes. It is therefore important that the work steps displayed at the assembly stations can be created easily and quickly and adapted again and again.

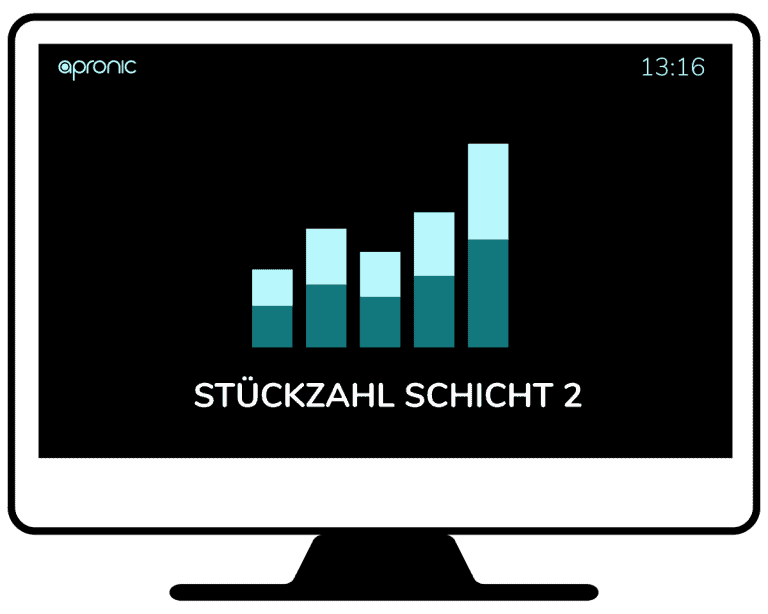

Similar to our Andon boards, work steps can be created in a graphical editor and then assigned to individual assembly stations. When creating assembly steps, we provide you with a variety of different widgets that can be freely placed on the screen using drag-and-drop. In addition to simple display elements such as actual or target piece counts, the editor also contains widgets for the local display of production line malfunctions, checklists for work content, nested material lists, pdf displays, and elements for video or image material to be displayed in the work step.

Once the work steps have been designed, they can also be dragged and dropped onto the individual assembly stations. All work steps can be provided with a target cycle time, so that it is possible to clock out the work stations directly. This makes it possible to see at a glance which assembly stations have a high workload and, if necessary, steps can be taken such as shifting work content to less busy stations.

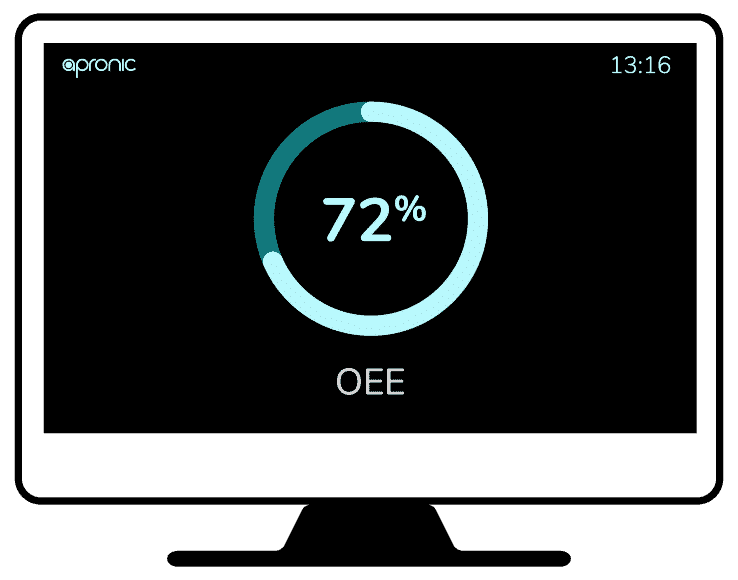

Andon boards as a useful addition to a worker assistance solution

Transparent:

Our Andon Boards

Andon boards provide key figures, inform about malfunctions or serve as a platform for other message text. In this way, all employees are on the same level.

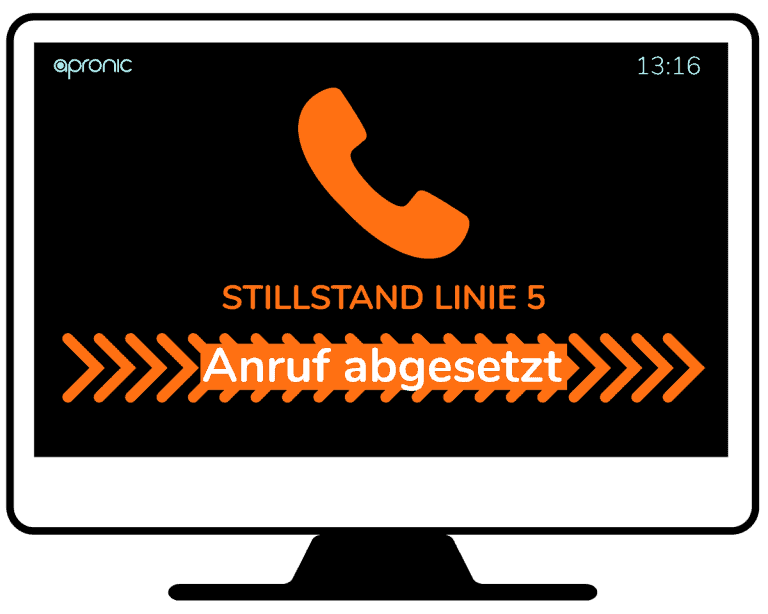

Signaling:

Alarming solutions

In the event of downtime, the right employee must be informed. The employee receives the notification either by phone call, e‑mail, SMS or app notification.

Communicative:

Digital fault messages

If a machine malfunction occurs, it must happen quickly! Digital input options save a lot of time and reliably call for help.

Optimizable:

Evaluation possibilities

The use of Andon solutions promises a reduction in disruptions. For this, data on disruption times and the reasons for the disruption are an indispensable source of information.

How does a worker assistance system benefit our customers and you?

Manufacturing processes are sometimes very complex and the impact of individual systems on them is therefore difficult to quantify. prodwatch is versatile and shows potential for savings and improvements in almost any production environment. Analyses at our customers show that prodwatch reaches the break-even point after less than one year. After using prodwatch, we were able to determine the following empirical values from customers in various industries.

Worker assistance solutions from apronic

Over many years, we have accumulated a wealth of experience that has been incorporated time and again into our standard solution prodwatch. We are happy to share this treasure and our innovative products and solutions with you. We are always happy to see new productions every day and to help our customers to optimize them. With us, you have a fast, experienced and flexible partner who, despite standard software, also keeps an eye on your processes. Feel free to contact us, we look forward to hearing from you!