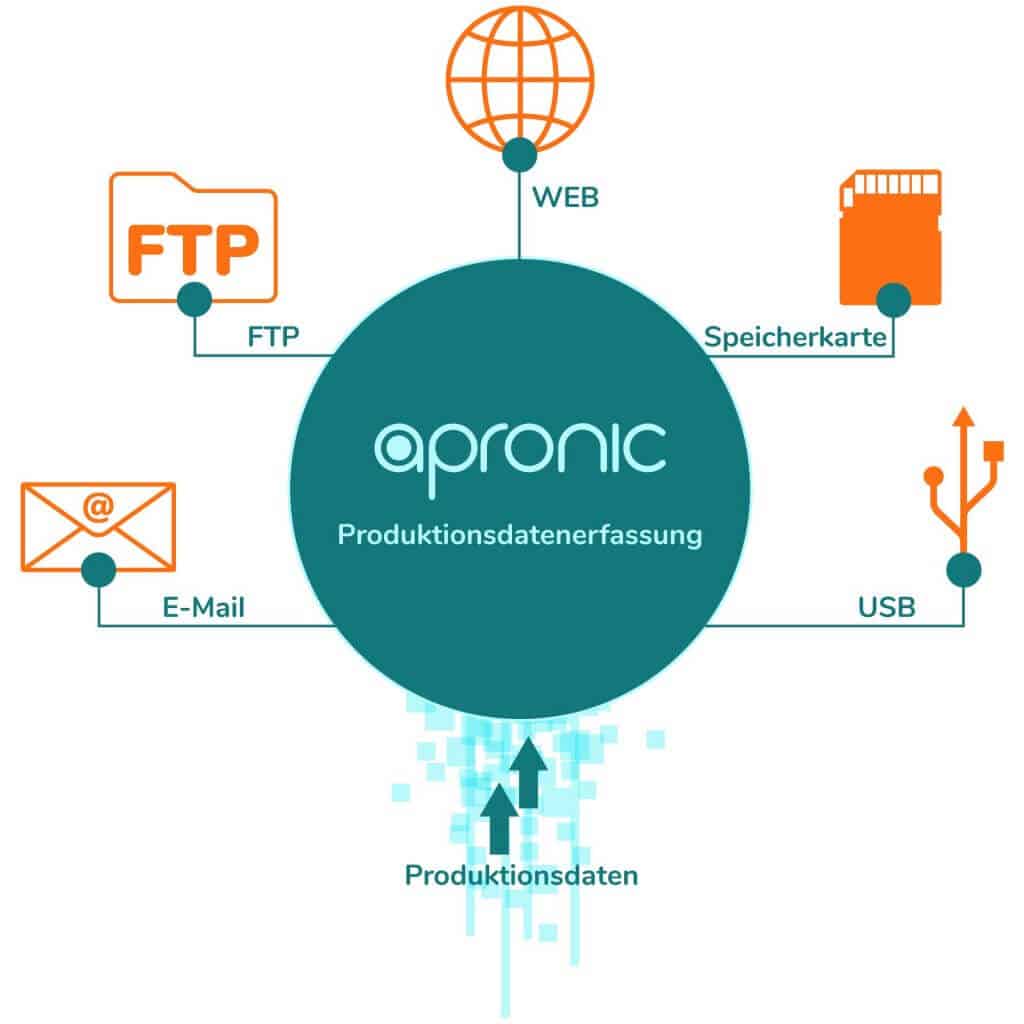

In many machines, a large amount of data has been lying dormant in the controls for a long time. Production data acquisition is playing an increasingly important role in digital production. In the vast majority of cases, however, machine data collection fails due to the large number of different protocols of the individual control systems. The data from many machines is therefore often neither collected nor evaluated. Yet this data can form the basis for optimising production or production processes. Our solutions help you to collect and analyse this data to optimise your production!

Together with our partners, apronic offers you the necessary tools to make your machine and production data usable for all systems above it, such as ERP programmes. We show you how to collect, visualise, link and use machine data. For example, create key performance indicators such as OEE or FPY and use them to monitor and optimise your production.

Red Lion’s FlexEdge™ Intelligent Edge Automation Platform brings together industrial data like never before. FlexEdge offers a scalable solution to integrate complex multi-vendor environments into digital transformation strategies, while providing a future-proof solution for changing application requirements. Regardless of the brand of PLC or other field device, the FlexEdge platform, run in conjunction with Crimson® software, enables connectivity to virtually any point in your production. Even analogue I/O data points can be integrated via the up to 10 hot-swappable I/O modules. Connectivity modules integrate WLAN, LTE and other communication technologies into the application. In this way, a seamless integration of data from the field level into cloud systems can be achieved.

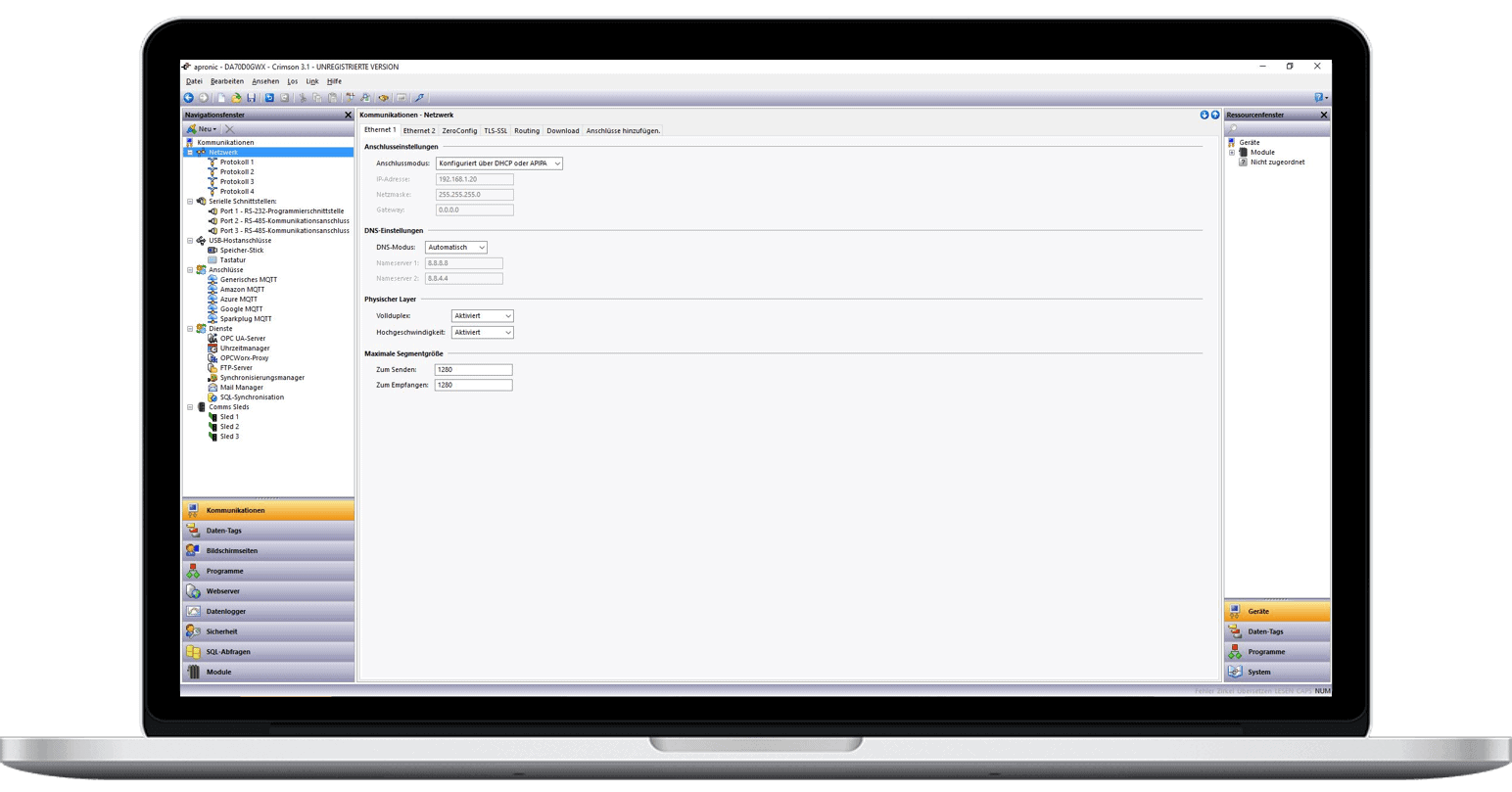

The Crimson 3.1 software combines the configuration of device data and the creation of custom applications. This free software platform is used to configure many Red Lion devices such as operating panels (HMI) or I/O modules. With the Crimson software, standard applications such as local data logging, the configuration of own websites with individual data points and the connection to Azure, Amazon or Google cloud systems are easily configured. In addition, the software offers numerous connectivity solutions and the possibility to use own code for the creation of complex applications.

As a global expert in communication, monitoring and control for industrial automation and networking, Red Lion Controls has been delivering innovative solutions for almost 50 years. Thanks to M2M technologies for automation, Ethernet and mobile communications, companies worldwide gain real-time data transparency that increases sales, reduces costs and increases productivity. Product brands include Red Lion, N‑Tron and Sixnet.

Red Lion is headquartered in York, Pennsylvania, with offices in the Americas, Asia Pacific and Europe. Red Lion is part of Spectris plc, the productivity-enhancing instrumentation and controls company. For more information, visit www.redlion.net.

As a long-standing partner of Red Lion Controls, we have extensive know-how from more than 120 projects. We know the requirements and needs of our customers and know that a certain flexibility of the solutions for machine data acquisition is necessary. We therefore accompany our customers from the actual recording of the requirements to the implementation of concrete applications in productions and machine parks. With our flexible hardware and the know-how of our application engineers and programmers, we offer our customers enormous added value in the development, integration and operation of machine data acquisition systems.

We at apronic are pleased to be able to work with such a flexible product portfolio and the full support of Red Lion as a certified and listed system integrator! Especially the automation portfolio consisting of the FlexEdge™ platform offers us the basis to be able to implement our customers’ applications 1:1.

apronic GmbH

Handwerker Gewerbepark 8

48282 Emsdetten