The above prices refer to a minimum contract period of 12 months. Only productive licences are counted. This means that we provide each assembly, andon and reporting station (e.g. smartwatch) with a licence. Administrative users who only use the configuration and analysis frontend do not need a licence! The monthly licence model already includes a maintenance and update service. Alternatively, we also offer licences as a purchase variant. In this case, a maintenance contract is recommended for function and security updates!

In both models we offer suitable hardware as an investment model. However, if the project is large enough, a leasing model for the hardware can also be used here. In addition, we are happy to offer training, workshops for process optimisation or other services.

Due to the diverse possibilities of production optimisation based on valid data, prodwatch offers an extremely fast return on investment. On the one hand, this is achieved through time savings in the area of downtimes and reporting times in the event of malfunctions. Thanks to fast reporting, faults can be rectified directly and downtimes can be reduced in the long term. On the other hand, another part of the efficiency gains comes from an increase in output: Employees can directly see which assembly steps are to be carried out in which order and do not have to laboriously look up this information in file folders or stacks of paper with work instructions.

Besides the enormous modularity and transparency, however, the greatest benefit of such a system lies in the collected data, such as processing times, reasons for and times of errors and much more. Transparent data can be used to identify where cycle deviations occur on the assembly line. These can then be specifically optimised by simply shifting work content to other stations. The detection of frequently occurring errors and their targeted elimination also leads to high efficiency gains in production and thus to a quick return on investment.

* Data based on customer feedback. Process optimisation takes place on many levels, which makes it difficult to measure many effects. Nevertheless, the above figures can be used as a rough guide for implementing manufacturing digitalisation.

In addition to the functions of the individual modules shown above, prodwatch offers flexible, comprehensive configuration and administration tools. These can be used in each of the modules and are accessed via a standard web browser from your desktop computer or a mobile device.

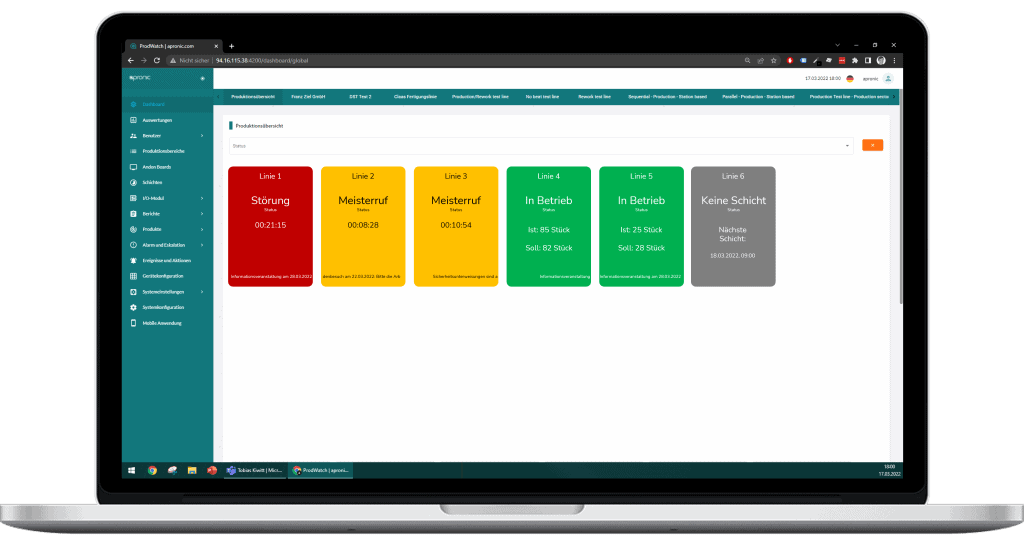

In addition to the configuration and management functionalities of the front end, prodwatch also comes with integrated dashboards, as shown here. This gives you as a production manager a permanent overview of all production lines, the individual workstations and current messages from production. The solution also includes a report and evaluation function with which shift reports and ad-hoc evaluations can be created.

Without robust hardware, any software is useless. Therefore, we offer a variety of different hardware components. We make use of our established supplier landscape and use standard market devices. We combine these in a sensible way and use them to create complete equipment for assembly stations, andon boards or for the personal equipment of production employees. In doing so, we always pay attention to particularly robust equipment that can withstand the rigours of everyday production and will give you pleasure for a long time. We adapt to your environmental conditions and design the hardware accordingly. Whether it’s simple assembly applications in the clean room, the tough daily routine in the foundry environment or the requirements from the food sector: we have the right hardware for every application!

For the workstations, we offer pre-assembled panel PCs with screen sizes between 7 and 32 inches. These are supplemented with mounting options and peripheral devices such as barcode scanners or RFID solutions and can be mounted directly on the workstations. We offer both standard components and very robust devices — for example for the foundry environment or the food industry.

We offer large-format screen solutions for your Andon board. With us, you will find above all robust, 24/7‑capable digital signage screens for professional use. In addition to commercially available hardware for production with low environmental impact, we also offer screen and housing solutions to meet the toughest environmental conditions such as the foundry environment. In addition, we supply suitable mounting solutions directly!

A smartwatch is ideal as an alerting device. It is always on the wrist of the relevant employees and thus reliably and quickly delivers fault messages to the right employees via vibration and acoustic alarms. We use standard smartwatches, mostly the Samsung Galaxy Watch series. These are already well protected against dust and moisture. We supplement this robustness with appropriate wristbands to be equipped against impacts in everyday production.

We offer a wide range of accessory components. These include ID systems such as radio barcode scanners for recording serial numbers. But also acoustic and visual alarm devices such as traffic lights or signal horns are part of our portfolio. We integrate control systems or test equipment of your line via input and output modules supplied with the system. In addition, we have interface converters to directly address the data in the controls via bus protocols.

We are happy to offer you a first live demo of our product prodwatch. In a one-hour appointment, we will show you which functions you can use. At the same time, we will gain an insight into your application and can directly work out solution proposals for software and hardware with you. We look forward to hearing from you!

apronic GmbH

Handwerker Gewerbepark 8

48282 Emsdetten