Our industrial smartwatch is the perfect companion for everyday production. It gives you an overview of current alarms, fault messages and the most important key figures of your production. Reported machine downtimes are immediately addressed to the right contact person in the company. This means that they can be rectified quickly and long downtimes avoided.

Together with our touch boxes or the prodwatch touch stations, you create responsiveness and transparency in your production. Your existing machinery and equipment as well as your MES/ERP software world are also an important source of alarms and production-specific data.

Reduce downtimes through fast and targeted alarming!

Accept alerts and provide feedback to employees when help is on the way!

Key figures, machine data and other production data available at any time!

Smart devices such as smartphones, tablets and smartwatches are an integral part of our everyday lives. We constantly receive messages as push notifications on our smart companions. Information is visible in every detail and gives us the opportunity to react quickly to news. Why don’t we use these technologies to stay constantly up to date in a professional environment as well?

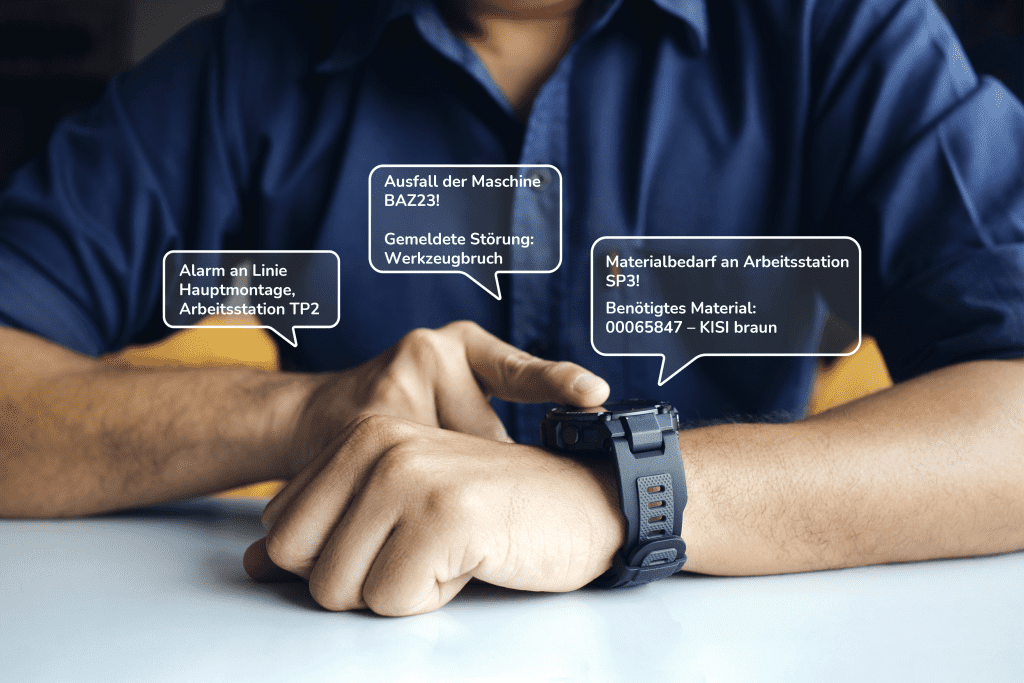

With the apronic smartwatch, you always carry the current status of your production on your wrist. This innovative, industrial smartwatch helps you react to production interruptions and other alarms as quickly as possible. With a tap of your finger, you accept these alerts on the watch, signaling to your employees that help is on the way. The clear fault list helps you keep track of all alarms.

The industrial smartwatch can also display selected key production figures or status messages of individual machines. For example, the cycle time of one or more lines can be read live on the wrist. In this way, you can carry piece counts, scrap rates or complex key figures such as OEE with you at all times. But also key data of particularly critical machines such as fill levels, temperatures or machine speeds can be called up at any time.

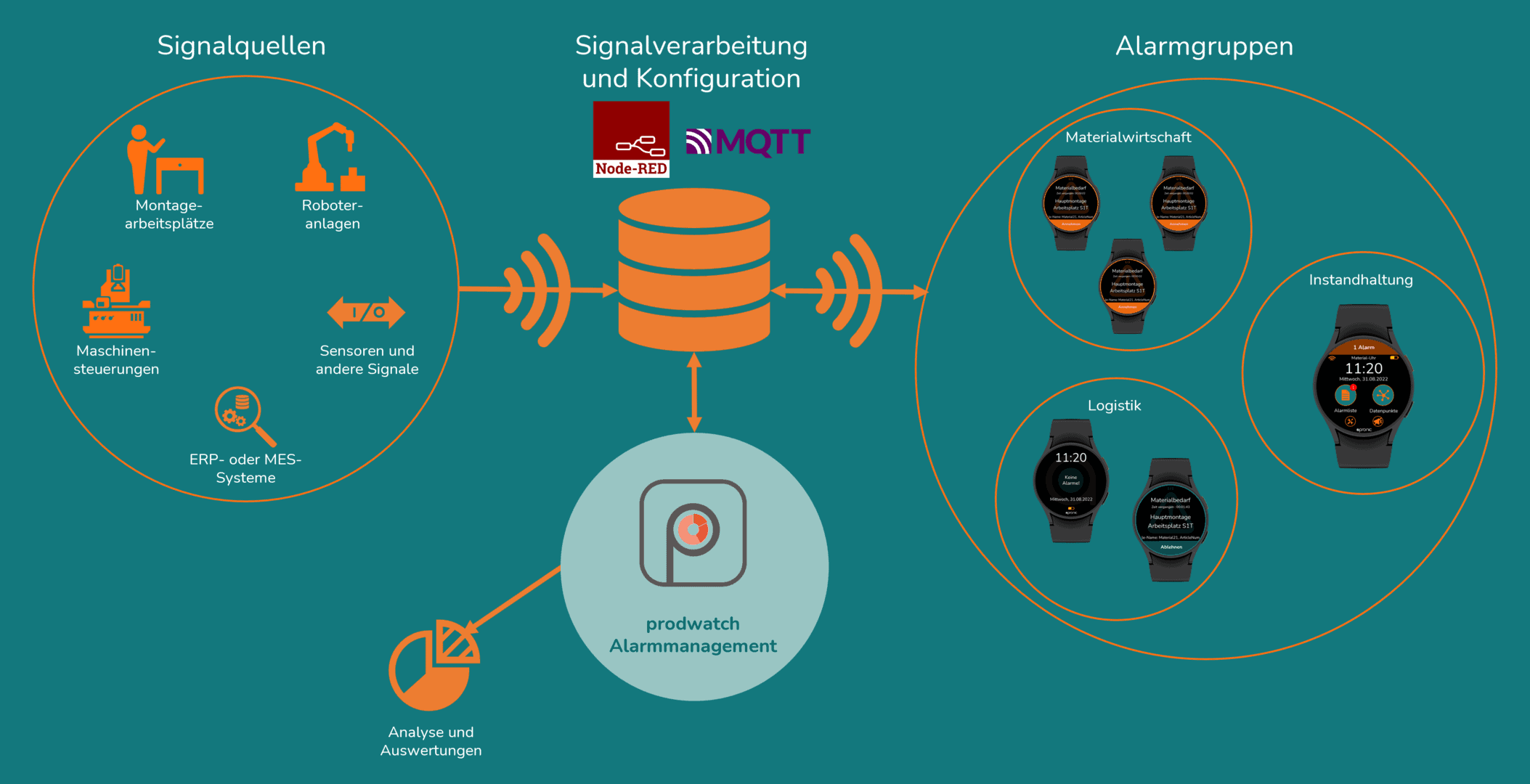

The industrial smartwatch can be linked to any machine, any ERP or MES system, and even directly to sensors. This is ensured by our intelligent system design and important interface modules. But the smartwatch can also be seamlessly integrated into the apronic ecosystem. For example, use our button boxes or touch panels to enter faults at the individual workstations.

By immediately reporting faults to the right contacts, they can be rectified as quickly as possible.

Employees receive information on the malfunction directly and can bring required materials or tools. The reporting of malfunctions is also simplified.

The open system architecture allows the apronic smartwatch to be used both standalone and in combination with prodwatch.

From the ERP and MES world down to the individual sensor of a machine: every data source can be connected!

The simple, intuitive user interface eliminates the need for training. We would be happy to supply you with a turnkey system!

Malfunctions can be reported both by employees and automatically. For this purpose, assembly tables can be equipped with a panel PC or a pushbutton station, for example. Machines or robotic systems can also send automated fault messages. For this purpose, the signals of the existing traffic lights are usually picked up via a gateway. This saves time-consuming programming of the controls.

In addition to people and machines, alarms can also be triggered via process control systems. A connection of individual sensors or other signal sources is also conceivable.

If an employee or a machine reports a malfunction, this is forwarded to the individual smartwatches via the MQTT broker. In addition, an acoustic alarm or a display on an Andon board can take place.

Alarming on the industrial smartwatch

If an alarm has been triggered on an assigned smartwatch, this is indicated on all configured smartwatches by a vibration and sound signal. Context information can also be added to such a malfunction. For example, a material number can be entered so that the wearer of the smartwatch can directly identify which material is required at the workplace in the event of a material shortage.

As soon as a fault message is accepted on one smartwatch, it is no longer displayed on other smartwatches. The smartwatch can be configured to continuously repeat the alert until a fault is accepted. These alarms can also be muted if, for example, a meeting is scheduled.

After the employee has solved the cause of the alarm, he acknowledges the alarm at the point of origin. This can be done either directly at the machine or by pressing the button again on the button box. After the alarm has ended, it is no longer displayed on the smartwatch. The alarm can also be reset time-controlled.

If an alarm is not accepted or acknowledged within a certain time, it can be escalated. In this case, the alarm is sent to another alarming group so that other smartwatches can see this alarming. Likewise, the employee who accepted the fault can also reject it again. The alert is then displayed again on all industrial smartwatches in the respective alert group. Other users can then accept it.

If an alarm is not accepted or acknowledged within a certain time, it can be escalated. In this case, the alarm is sent to another alarming group so that other smartwatches can see this alarming. Likewise, the employee who accepted the fault can also reject it again. The alert is then displayed again on all industrial smartwatches in the respective alert group. Other users can then accept it.

Both the smartwatches and the individual machines, plants, touch panels and all other sources of alarms are connected via WLAN to the central MQTT broker. This software is the hub for the alarm messages and the messages to the individual smartwatches. On this server, which is hosted either in the cloud or in your IT infrastructure, you will find a Node-RED instance in addition to the MQTT broker. Node-RED is a low-code platform that allows you to create simple rules for alerting. For example, Modbus registers can be read from machines and the information from them can be given to the smartwatch in the alarm message.

On request, we can supply you with a turnkey, fully pre-configured system of watches and the corresponding server infrastructure. So you can work directly with the alarm system and the industrial smartwatches. The configuration can also be done by yourself, for this we will gladly provide you with all tools and assistance.

In combination with our manufacturing digitization solution prodwatch, extensive evaluations can be created from the reported alarms and the corresponding feedbacks. The industrial smartwatches have a native interface to prodwatch, so that it is possible to easily create alarm groups and bring appropriately configured alarms to the smartwatches.

Connect Smartwaches and machines to the WLAN, configure easily and start directly

The central server can be hosted either in the cloud or in your IT infrastructure

Smartwatches can be easily added to an existing system

The apronic smartwatch can be used as a standalone system or in combination with prodwatch

In addition to the alarm application, the industrial smartwatch can also be used to display data points. This makes it possible, for example, to make the remaining cycle time or also temperature or fill level displays accessible on the wrist. In principle, every data point of a machine or an IT system can be brought to the smartwatch via the MQTT topics and visualized there.

Via a folder structure, it is possible to group these data points in a meaningful way, so that a data collection is formed for each of your machines, workstations or production areas. This helps your employees to get an overview of the production at any time. Examples of such data points can be:

The alerting application is executable on all smartwatches that are operated with the Wear OS by Google operating system. Basically, we like to use commercially available devices since they already come with dust and moisture protection. Only the shock protection leaves much to be desired in many of these models. However, this shock protection can be obtained via corresponding accessories. We offer robust wristbands and display protection foils for this purpose.

Cost effective hardware

Any smartwatch with wear OS by Google can be used

Dust and moisture proof

Most smartwatches have an IP68 protection rating

Protection against manipulation: Kiosk mode

All functions of the smartwatch can be locked for users if necessary

Exclusively WLAN required

The smartwatches do not require a connection to a cell phone and only need to be connected via WLAN

We would be happy to present our smartwatch application, the hardware and the possibilities of connecting (alarm) signals to you in an appointment. We look forward to hearing from you and getting to know your application!

apronic GmbH

Handwerker Gewerbepark 8

48282 Emsdetten